STAND Up!: high level technology and deep neural network learning mechanisms as innovative solution for high quality fabrics detection in Tunisia.

In the context of textile production, visual fabric inspection is a systematic evaluation in which defects are identified and helps to understand the quality of the fabric in terms of construction defects, colour variations before the garment is produced. At present, defect detection is carried out manually through very repetitive work that involves the possibility of human error and long inspection times with high costs, oftenly leading to the production of second-rate garments, which represent a great loss for the company and considerable pollution.

In the framework of the multiple challenges on circular and sustainable innovation for the textile and fashion sector, opened in Tunisia and launched on the Switchers Open Eco-Innovation platform Texpro Corp, a local vertically integrated company specialised in Denim, casual & outdoor wear has launched a challenge to to tackle this issue and to look for a computer-based inspection system for identification of defects in the woven fabrics using high quality images image processing.

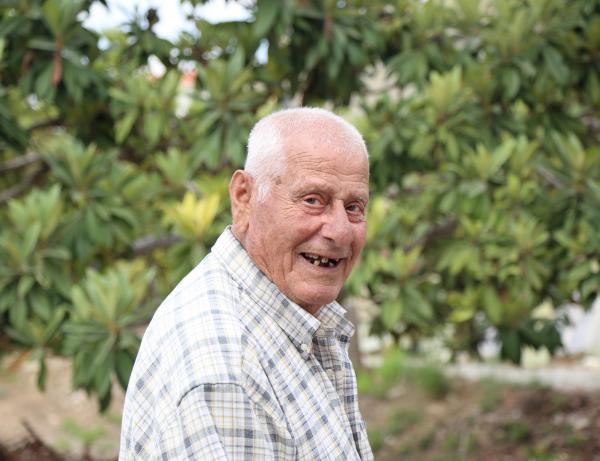

The winning solution selected by the company with the support of STAND Up! partner CITET has come from VIZmerald startup, an electronics and smart software engineering new Tunisia actor motivated by the creation of quality and esthetic designs and is name is ViAFaM (Visual Automatic Fabric Marker) which aims to combine camera-based texture analysis and automatic marking marking for the purpose of automatic fabric defects detection.

This solution helps human operators in their repetitive quality assessment tasks introducing a new defects detection system that profits from the most recent breakthroughs in deep neural network learning mechanisms with a technology level very close to that of human intelligence.

The added value includes the automatic defects detection vision-system coupled with a robotic marking device for capturing/marking defects. By this fact VIAFaM can accelerate the production rates while minimizing 2nd quality clothing and solid defects waste, thus improve the ecological impact of the manufactory as an ultimate goal.

As a direct impact, the solution thus includes the disposal of discarded solid waste of defective fabric and also the disposal of second-rate garments, but also on an indirect level the AI-based software will be capable of keeping track of the best suppliers that minimise the waste outcomes.

The development of this solution still requires optimisation, study and cost-balancing phases for its full utilisation and the analysis of some data sets and proprietary software To this end, as part of the STAND Up! eco-innovation voucher scheme, the unit will be awarded with a voucher set worth 20,000€.