MED-InA in Spain supports Laüd Recycled, 100% recycled and sustainable shoes

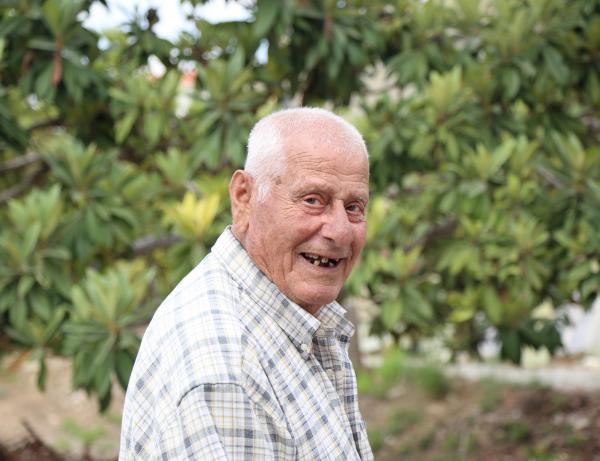

Can you briefly introduce yourself and tell us about your project?

I am Oneida Román, founder of Laüd Recycled, a sustainable footwear brand that aims to combine fashion and sustainability. Today there are sustainable footwear brands, but many are far from the concept of fashion. In my case, what I wanted to do with the project was to make it closer to the end consumer, a more normal product.

Within the project, I am the only one who currently works directly, but I have different companies with which I collaborate externally. There is a designer who works for the project but who also works on other projects, I work with a marketing agency, so in the end I have always collaborated with these external people who are involved in the project, specific to each need I have. This is the current way of working, because until it becomes economically sustainable, I can't have more people involved, but when we can have another person directly involved in the project, everything will be more unified.

I'm from Elche, a city in the Valencian region in Spain, where the footwear industry is very traditional: many footwear companies. It is one of the industries where great effort is made in terms of the development of sustainability in all sectors. There is a wide variety of recycled fabrics, organic fabrics, cottons... So it gave me the possibility of generating a finished product of sustainable footwear. What I really did was to take everything that the industry was developing and give it shape. As a project, what we do is collect all the development carried out by the big companies that have laboratories, that can develop it, but cannot materialise into in a finished product for the consumer.

I work with different suppliers depending on the material and there is a company nearby that already recycles the plastic. My supplier transforms it and I acquire it and use it for the design of the product. I manage the purchases from the suppliers, and I send it directly to the factory where they are in charge of cutting the pieces, sewing them and making the shoes. The factory is external, they work for me, but they also work for other brands.

When and how did you come up with the idea?

In terms of development and research, I started in September 2019, with the phase of looking for suppliers, materials, market research, testing the ground, the competitors that existed, the supply, the demand... And in 2020 I started with the development of prototypes, but the pandemic meant that everything was delayed, and it wasn't until January 2021 that the project really saw the light and work and sales began, but this first year was quite complicated; 2022 was a little better. Little by little it's starting to move.

How will the prize you have won help your project and what are the next steps?

When you start a project you invest a lot of money on the marketing side, and that is money that we call "burning money" because you invest it, but you don't get it back right now. So of course, for me, when I applied for the programme, my idea was to invest in the marketing part, to be able to continue investing money so that the brand is known and to be able to build brand positioning. I told the people I work with, "with this money we are going to try to do other things better, we are going to invest more, we are going to do a remarketing campaign to try to attract more people".

The objectives I have right now is that we have just integrated with Zalando, the marketplace, and we believe that this is going to be very good for us when it comes to internationalisation, because we have chosen 3 key markets: France, Germany and Belgium. Internationalising the brand from the beginning is key for development. We also need to grow within Spain, because it is a Spanish brand and it has to have a presence in Spain. This is in terms of the company's growth.

Besides, for next year I plan to have a new person joining the project.

The MED-InA prize came with a 3-month incubation at IDEA Alzira, the local development agency providing training, labour, trade and entrepreneurship coaching; what did you expect from that and what did you achieve?

Normally, programmes like this for entrepreneurs that give you economic prizes offer you extensive training at the beginning and then you have shorter, more personalised sessions. What I have seen in this programme with Alzira is that the training we receive after knowing that we have won is very extensive, very long, many hours. And depending on the stage of the project, maybe you need 200 hours of counselling, but maybe you only need 100? So I told them that, in my opinion, what would be more interesting would be to start with more sessions with specialists in the sector, one or one and a half hours of specific training, and then when they tell you "you've won" you have 10 hours with an expert to clarify your specific doubts. At the beginning we did 4 sessions or classes with a specialist, which I found very interesting. Then we presented the project, and when they told me "you've won it", they told me "now you have 200 hours to talk to this person". But I don't need 200 hours? Sure, it's always a good thing to have the point of view of an expert, who can always help you. But I think it's better if they put for example only 100 hours, and instead of putting 4 classes of specialists, put 8 classes of specialists of the sector, circular economy, recycling...

How do you see your contribution to waste reduction efforts and/or a more circular economy?

I developed the project for several reasons: to bring fashion closer to sustainability, and then because I want to promote work ethics. Here in Spain, we complain a lot that there are no jobs, that wages are low, but if we don't consume or manufacture products here, it will always be like that. Besides, all the brands that manufacture in Vietnam, India, China or countries like that, their sustainability standards are not the same as ours. Waste management within the companies themselves here in Spain is not the same as how it can be managed in China... That is also why we encourage national manufacturing, because if you are going to distribute within Europe, it is more interesting to manufacture here.

These are concepts that go hand in hand: sustainability, national manufacturing, ethical work... everything goes together, there are many concepts that are related.