MED-InA in Jordan supports Teenah's project on women's employment through upcycling

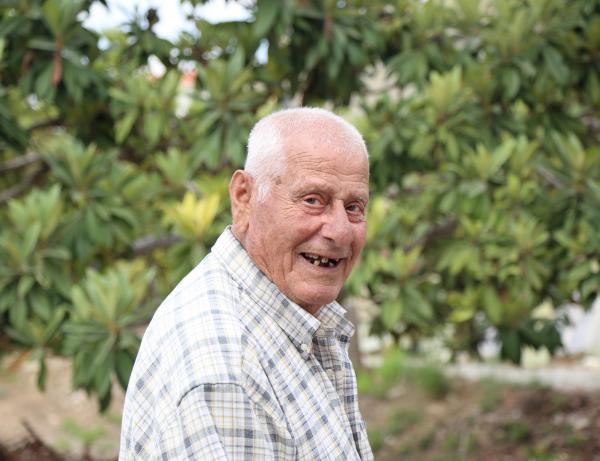

Can you introduce yourself briefly, and tell us about your project?

My name is Raneem, I’m a social entrepreneur having started previous social enterprises in Jordan, among which Teenah, the first ethical merchandising in the Middle East. Ethical merchandising means that we produce products that are sourced, produced, delivered and shipped in an ethical and responsible method. We do eco-friendly products by working with both refugee and host communities in Jordan. This project is called E3ada, which means “remaking” or “reusing” in Arabic. It’s dedicated to upcycling materials: our main focus is textile and a little bit of plastic. Upcycling means we add value to previous waste, and we add some production processes to have an end product that can be sold and available for end users. And of course, we’re doing it in a responsible way.

The main focus of this project is in Irbid, north of Jordan, where we will be working with the local community, local ladies, upskilling them, teaching some skills, they will have some training to learn how to upcycle basic materials and make them an end product. In order for them, as a long-term vision, to have their own upcycling processes and products. So it’s like we’re unleashing the designers and artists inside each of them.

Teenah is a full profit business: we export to Europe, the Gulf countries and Japan, and we’ve been running for more than 4 years, but the specific E3ada project focuses on Irbid, with production and operations taking place locally, but we will be promoting the end products to our clients and markets abroad. The products are diverse: bags, boxes, any kind of gift materials, and we will promote these items and products in the Gulf countries and Europe because we already operate there: we are mainly an export company, businesswise. We work in cross-border trade, marketing, logistics, because we also import raw materials from Pakistan and Turkey, we manufacture in Jordan and we export and sell to other businesses… Our broader business imports some raw materials, but E3ada is more focused on local raw materials.

The range of products sold can be found on the online shop, the standard items of our business, and hopefully by the end of this project with TTi we will launch a dedicated website for E3ada, because it targets different segments. Our main website targets businesses and industrials, but for E3ada we want to target individuals and different segments, as it has a different approach both on the ground and the people it involves, and in terms of customers targeted.

The scope of our work goes from getting the used materials all through the manufacturing process and to export. We started with a small pilot where we worked with local shops that make furniture: we collected the waste and leftover fabric and worked with local Community Based Organisations (CBOs), local women to work with these materials and we came up with new products with this pilot and people loved it! That’s why it encouraged us to take it to another level and work on more products and high end finishing. The plan is to get more CBOs involved so that local ladies can work at the different stages of the project: collecting, sorting, manufacturing. It’s all sourced locally, and the next step hopefully is trying to arrange with the municipality a project to encourage people to bring such waste, instead of throwing it away, to the municipality so we can use it: it’s a win-win situation. We focus on textile but a little bit of carton, paper and textile plastic, maybe we’ll be adding concrete, sand: we’re getting some information from the municipality on the quantities and types of waste so we can articulate which kind of products we can make out of this waste.

We are based in Irbid, in the development zone, a semi-industrial area. We have between full-time and part-time around 38 people in Teenah, and dedicated to the E3ada project we’re starting with 4 people and hopefully we’ll kick off from there. The 38 people include the ones working in production, logistics…

When and how did you get this idea?

My background is mainly civil engineering, I also have a degree in social entrepreneurship; almost 5 years ago I started working with refugee and host community projects, shelter renovation, renewable energy, and I got the idea from working with the beneficiaries directly: they wanted sustainable income instead of instant cash and I thought: “what could be a simple product that they can learn to make, but also has a high demand?”. That is where it all started, in 2015/2016.

How did the orientation session and support by TTi help you prepare the pitching event?

I attended the orientations, of course they helped, because we had this idea and we needed an expert view on it to articulate it into a self-sufficient model to translate it into reality!

How is the prize you won going to help your project, and what are the next steps? What are you expecting from the TTi incubation that you are going to benefit from?

For this project, mainly we want to articulate an on-the-ground line where we have this upcycling production unit; we want to do it with a local organisation and the municipality, where people will own it; it’s from people to people so they can create income. We also want to create this marketplace for E3ada where people will learn to do upcycling. We want to bring the upcycling mindset to the local community so they can use it as a business where they can generate income from, that’s the long term plan.

Regarding TTi (the incubator selected by MED-InA in Jordan to support 4 circular economy project holders), we have been in constant demand for IT support on how to formulate this marketplace, but also on the business model, how to articulate all the idea into a full cycle of closed loop process starting from identifying the product, product development, sourcing the material, producing them, working with the local community, with the women, teaching the skills: so we’re getting support in all these steps. In the mentoring and coaching sessions, we worked on the business model, product development, sustainability aspects, and lastly the financials, which is great!

We’ve had one-to-one sessions, business-focused and tailored to our model and project, and we’ve had group sessions on sales, finances and sustainability, because all the MED-InA participants are within scope regarding sustainability and circular economy.

Now we aim to launch the final products in the regional market: so we’re working on product development, preparing sales material, presskits and on the other hand working with the local community: we’ve already selected the partners, materials, the staff, and we’re starting the training soon.

We wanted to include the community not only collecting and providing the waste but also in the sorting, the production and generating the income, so it’s a closed loop from A to Z.

How do you see your contribution to the efforts towards less waste and/or a more circular economy?

Because we work in Irbid and in an industrial zone, we notice the waste all the time, and I think the idea from E3ada was that we wanted to include the community, and have a realistic and inclusive model. This is how I always think of things: simple, small steps that anyone can take. Waste in Irbid is mostly plastic and a little bit of textile. We focused on textile because it’s our expertise so we didn’t want to overpromise and underachieve. We wanted to include the community not only collecting and providing the waste but also in the sorting, the production and generating the income, so it’s a closed loop from A to Z.