MED-Ina in Jordan supports Ivvest, a cost-efficient, scalable & easy indoor farming solution

Can you introduce yourself briefly, and tell us about your project? When and how did you get this idea?

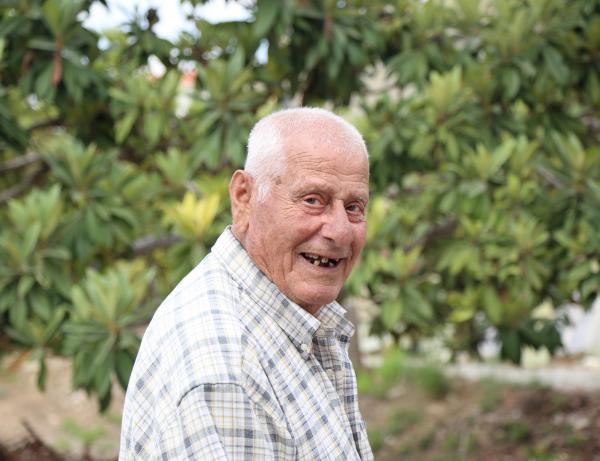

I am Abdel Rahman Alzubaidi, CEO of Ivvest; architect by education and Agripreneur by passion. My passion for entrepreneurship has got me through many great experiences, lessons and failures, which eventually led me to start Ivvest back in late 2019.

With COVID, lockdown, supply chain problems and food security challenges in our region, an efficient solution to grow our food consistently all-year-long had to be created from the region to the region.

Therefore, throughout 2 years of research and development integrating science and technology we were able to create The Capsule. which is a plug-and-play, highly efficient, profitable, scalable and smart container farming unit. Each unit is empowered with IvvestOS, that brings intelligence to the unit. Together with our proprietary designed vertical farming system and growing lights we enable producing 400+ plants/m2, while reducing 40%+ of electricity consumption to generate 5x return on investment than greenhouses with 3 years faster payback.

Such an indoor farming unit is globally priced at $100K-$150K, however to make our solution even more accessible, we designed a unique local market driven business model that is based on offering it to agricultural entrepreneurs at cost-price of $30K. In return to receiving a revenue share from sales and a monthly subscription fee that covers many services including market access, supplies, location, technical support and the usage of our indoor farming operating system IvvestOS.

Our team consists of experts and professionals with diversified background covering all of the aspects needed for Ivvest to grow including architecture, agriculture, supply chain, IoT (Internet of Things, connected devices), software, sales and marketing.

What does “The Capsule” look like? Can this technology be used by non-professional farmers?

The Capsule looks like the shipping container, however it is fully custom-built to meet our indoor farming system needs and dimensions as well as to be scalable and attachable with future expansion units. Our indoor farming operating system IvvestOS, controls the most sensitive operations including climate, CO2, nutrient solution dosing, lighting and irrigation. Thus, enabling anyone with no previous background in agriculture to be ready to operate The Capsule within less than one week of training.

When you provide the solution to a customer, what is it they are getting?

The Capsules includes two main components or elements: the hardware, which is the vertical farming system, the lighting system and the IoT components, and the other components for ventilation, for climate controlling and CO2 controlling. We have a software called IvvestOS, which controls all of the parameters, enabling us to control and customize the environment for each different type of crop. For example if you’re growing lettuce, the temperature, humidity and CO2 levels will be different than if you’re growing basil. Same applies to the nutrient solution and the percentages you need to maintain. Good luck if you wanted to do that manually! This is why we developed this kind of software, so we can decrease the error rate and make it as accurate as possible, and as automated as possible, so that the need for human intervention and presence all year-round is not mandatory. For example if it snows and the roads close and you cannot go to your container, or during lockdown, such a solution enables you to keep the production going.

We are currently finishing the production of the first unit, as we started in an apartment in Amman. In September 2021 we got our first round of investment and now support from TTi (the incubator selected by MED-InA in Jordan to support 4 circular economy project holders), so that has motivated us to expand and enabled us to rent land starting from late 2021.

Each farmer/user will have the possibility to customize their own farms through IvvestOS, we do not want to be part of the operations, rather supporting them technology-wise or providing consultancy regarding the parameters to adjust using our containers. Until late 2021, we used to think of a different business-model, in which we would have retained the technology and hired farmers to use it to produce for us. We were invited to Dubai by the Jordanian Ministry of Investment to join a panel, and had the opportunity to interact with many Dutch companies working in the controlled agriculture industry. We understood how big the opportunity was to sell the technology in the GCC (Gulf Cooperation Council) area specifically, so we changed our business model in this way, thinking how we could further expand.

We do not have any patent yet, because we are still working on developing a new type of system, which we will file patent for (i.e. the next generation of our containers).

We are planning to have traction for the whole operations, which will enable us to have higher quality assurance on operations, optimize it and later having some AI that will help farmers benefit from each other’s data to improve their crops.

How is the prize you won going to help your project, and what are the next steps?

We had one mentorship session with Belal from TTi, and to be honest I was not expecting much beforehand, however the guidance, recommendations and result we received from TTi turned out to be very beneficial!

The grant enabled us to develop our indoor farming systems more and achieve technical milestones including finalizing the nutrient solution dosing and growing lights controlling and monitoring.

What are you expecting from the TTi incubation that you are going to benefit from?

One of the most important things that we are expecting is networking opportunities, and the possibility to use TTi’s network, which is already happening through the introductions to Del Monte (a fresh fruit and vegetable company) and another person who is a purchasing decision-maker at Carrefour (a retail and supermarket brand).

Yazeed from TTi is doing a great job asking us exactly what kind of sessions we are interested in having, so the staff members attending depend on the session topic: either me or 2 other people whether it’s marketing related or sales related or finance related, etc.

How do you see your contribution to the efforts towards less waste and/or a more circular economy?

One of the great advantages of our solution is that we are reducing food waste from the traditional greenhouse production, up to 100,000 dollars per reseller per year, because retailers have to cover up to 50% of the cost from the crops they buy so you can imagine how much of crops is wasted. Using indoor farming technology, the damage to crops and subsequent waste percentage is less than 10%, so that makes a big difference. In addition, water consumption is 90% less, land use and need is over 90% less because we produce 10-15 times more than traditional farming per square meter.

All of these things go together in supporting the circular economy, and one other thing, which is more related to indoor farming: energy consumption, one of the most talked about topics, because of lighting consumption. We started with lighting solutions from the market, but due to really high consumption, we are currently designing our own custom lighting solutions, to become much more efficient in terms of output and energy consumption.